REDUCE - REUSE - RECYCLE

The 3Rs—Reduce, Reuse, and Recycle—are the basis for a sound material lifecycle. We promote it in the home, in the workplace, and in industry. It just hasn't reached Lithium batteries yet. Lithium batteries for use in electric vehicles (EV) and in energy storage (home) are supposed to be humanity's answer to the global quest for NET Zero emission climate goals. The International Environment Agency (IEA) estimates 2 billion EVs need to be on the road by 2050 to achieve net zero.*1 Is there enough Lithium and other required minerals to achieve this ambitious goal?

REDUCE

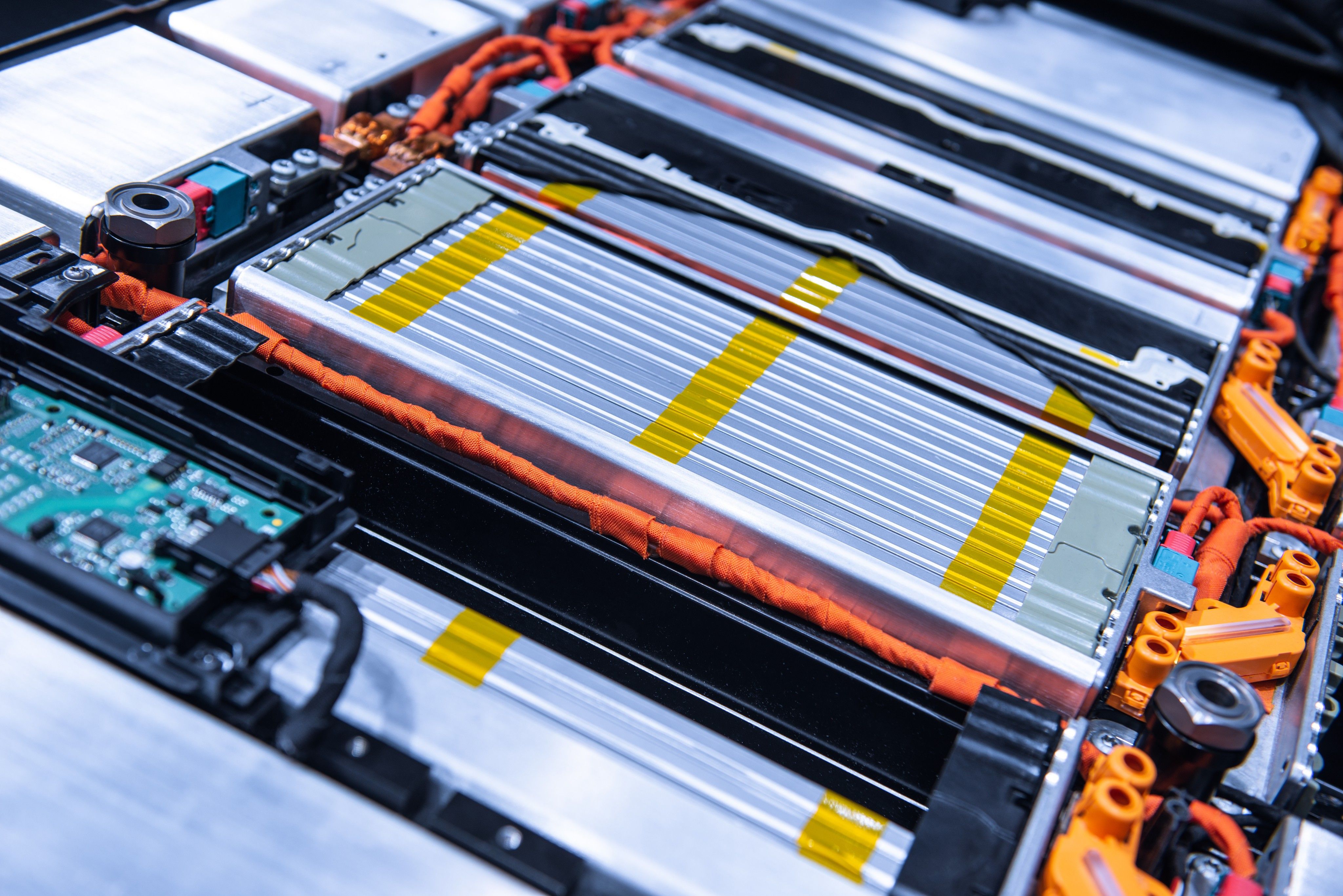

As part of the first tenet in the 3Rs, research is constantly being done to reduce the special metals required to produce Lithium batteries. There are many different chemistries that battery manufacturers can choose from, and scientists are continually testing to find the best combinations to produce a battery with the smallest footprint, that has the maximum amount of energy, and that delivers the power safely.

In early Electric Vehicles, Lithium Cobalt Oxide (LCO) and Lithium Nickle Cobalt Oxide (NCA) were the batteries of choice. However, due to the humanitarian cost of using cobalt*5, scientists have looked for ways to minimize or do away with it altogether. They have now discovered battery chemistries that work just as effectively. Scientists are also reducing the need for other valuable materials like nickel and manganese.

Lithium

Each car battery currently requires about 8 kg (17.6 lbs) of Lithium.*1 The hunger for electric cars has increased dramatically as sales of electric cars are estimated to grow seven times between 2020 and 2030. If there are no changes to a battery’s Lithium requirements, in the year 2030, electric car batteries will require 2 million tons of Lithium. The estimated total of the world’s global Lithium resources is 89 million tons,*2 of that Lithium reserves stand at 22 million tons. (The reserves are based on available Lithium in feasible locations that can be mined at the current price and current technology.) At 8 kg per car battery, 22 million tons is enough to produce batteries for 2.75 billion cars. To reach NET ZERO emissions by 2050, the world needs 2 billion battery-electric, plug-in hybrid, or fuel-cell electric vehicles on the road. But because we also use Lithium for various other purposes, such as pharmaceuticals, glass, and ceramics, powering 2 billion cars from only our Lithium reserves may be difficult. 71% of mined lithium is used for batteries, while 14% is used for glass and ceramics.*2

“Reduce” is an important aspect of the 3Rs, but it may not be enough before all the world's Lithium is consumed and before the planet can reach its NET ZERO climate goals.

REUSE

Batteries reach their end of life when they no longer work properly for their intended purpose. In the case of electric vehicles, the warranty of most batteries is 8 to 10 years or 160,000 km (100,000 mi). However, the latest industry expectations project EV batteries to last 15 to 20 years or 160,000 to 320,000 km (100,000 to 200,000 mi).*6 In many cases, the batteries will outlast the life of the vehicle itself.

There are often many cycles left in EV batteries at the end of the life of a vehicle. These batteries can either be re-purposed or reconditioned for further use.

There are now several companies that buy used EV batteries for use in energy storage. These businesses have re-purposed EV batteries to store solar energy, which is sold back to the grid at peak times to generate maximum revenue. This activity helps balance the grid and provide energy when it's most needed.

As for energy storage batteries, such as those used in whole-home backup or off-grid applications, there is little or no life left at the end of life. Once the cell voltage reaches 3.0 V per cell, the battery has minimal storage capacity. With virtually no capacity left in the energy storage battery at the end of its life, the only option is recycling.

RECYCLE

Recycling, the final step in the 3Rs, is important to keep the material lifecycle alive. As of 2022, recycling Lithium batteries is virtually non-existent. Depending on where you live, 2 to 5% of rechargeable Lithium batteries are recycled. By the year 2030, it’s estimated that there will be 2 million tons of used Lithium batteries generated per year.*4 Without dramatic changes, most of these batteries will end up in a landfill.

China is leading the way in recycling, as the Chinese government has made recycling rechargeable lithium batteries mandatory. Although China is one of the main producers of Lithium and controls 80% of the Lithium supply chain,*3 China is also the world's biggest consumer of EV batteries. China's reserves are not very large, making recycling vital for their market.

The following are a few reasons why recycling Lithium batteries is not mainstream in the rest of the world.

-

Logistics. Lithium batteries are considered hazardous goods. As a result, consumers cannot easily send spent rechargeable Lithium batteries back to the original manufacturer or to a recycling facility. This is unlike Lead Acid batteries. Even though the main components of Lead Acid batteries —lead and sulphuric acid— are hazardous, the shipping of Lead Acid batteries is not considered hazardous goods if used batteries are sent to the original manufacturer or a recycling facility. This caveat currently does not apply to Lithium batteries.

-

Volume. If the life of EV batteries is 15 to 20 years, and it's the year 2023, we can begin seeing Lithium batteries from the 2008 sales year. EV sales in 2008 were still so low there is little data available on how many were sold worldwide. The first year with sales data available on ev-volumes.com is 2013 when 206,000 EVs (including plug-in hybrid) were sold. Used Lithium batteries from the 2013 sales year would start appearing in 2028, but even then, the volume may be too small to justify local or regional recycling facilities. When it comes to Lead Acid batteries, volumes are so large that they are recycled everywhere. Enough so that shipping regulations were adapted to allow shipments of Lead Acid batteries to the manufacturer and to recycling facilities.

-

Cost of Recycling. It is currently cheaper to mine for Lithium than it is to recycle Lithium. Recycling Lithium batteries are expensive due to factors such as the cost related to shipping hazardous goods, the recycling technology for Lithium batteries being unrefined, and recycling Lithium batteries lacking economies of scale.

The current method of recycling Lithium batteries includes shredding the battery and then smelting to separate the different metals. Others have suggested methods that include reusing the cathode crystal structure.

Scientists and engineers are testing to find optimal recycling technologies, which will only be possible with economies of scale. Some battery manufacturers have opted to lease warehouse space to store their used batteries and wait for the recycling market to mature, whereby recycling facilities will pay for used Lithium batteries.

Conclusion

The 3Rs—Reduce, Reuse, and Recycle—are the basis for a sound material lifecycle. Regarding lithium batteries, the planet is still working on the final chapter, recycling. Through extensive research and development, manufacturers have reduced the raw materials required to produce each Lithium battery. And used EV batteries find a second and sometimes a third life as they are reused in energy storage. Recycling is the missing piece for a sound material lifecycle of Lithium batteries.

While there may be other renewable energy choices to power our vehicles, Lithium batteries will probably remain dominant if there is no dramatic shift in the price of Lithium. This is ironic since Lithium's affordability is a factor promoting the mining of Lithium over the recycling of Lithium batteries.

Once the cost of recycling Lithium batteries decreases dramatically, through lower shipping costs, economies of scale, and advancements in recycling technology, Lithium batteries will be able to continually power electric vehicles and provide energy storage to help humanity battle the climate crisis.

*1 World Economic Forum, “The world needs 2 billion electric vehicles to get to net zero. But is there enough lithium to make all the batteries?”

*2 Government of Canada, “Lithium facts”

*3 International Energy Agency, “Global Supply Chains of EV Batteries – Analysis - IEA”

*4 C&EN, “It’s time to get serious about recycling lithium-ion batteries”

*5 Council on Foreign Relations, “Why Cobalt Mining in the DRC Needs Urgent Attention“

*6 Battery University, “BU-1003a: Battery Aging in an Electric Vehicle (EV)“